A Top To Bottom Electrical Business Doing Everything From The Power Pole To The Power Point, All Things In Between including Generation and Renewables Projects

A Top To Bottom Electrical Business Doing Everything From The Power Pole To The Power Point, All Things In Between including Generation and Renewables Projects

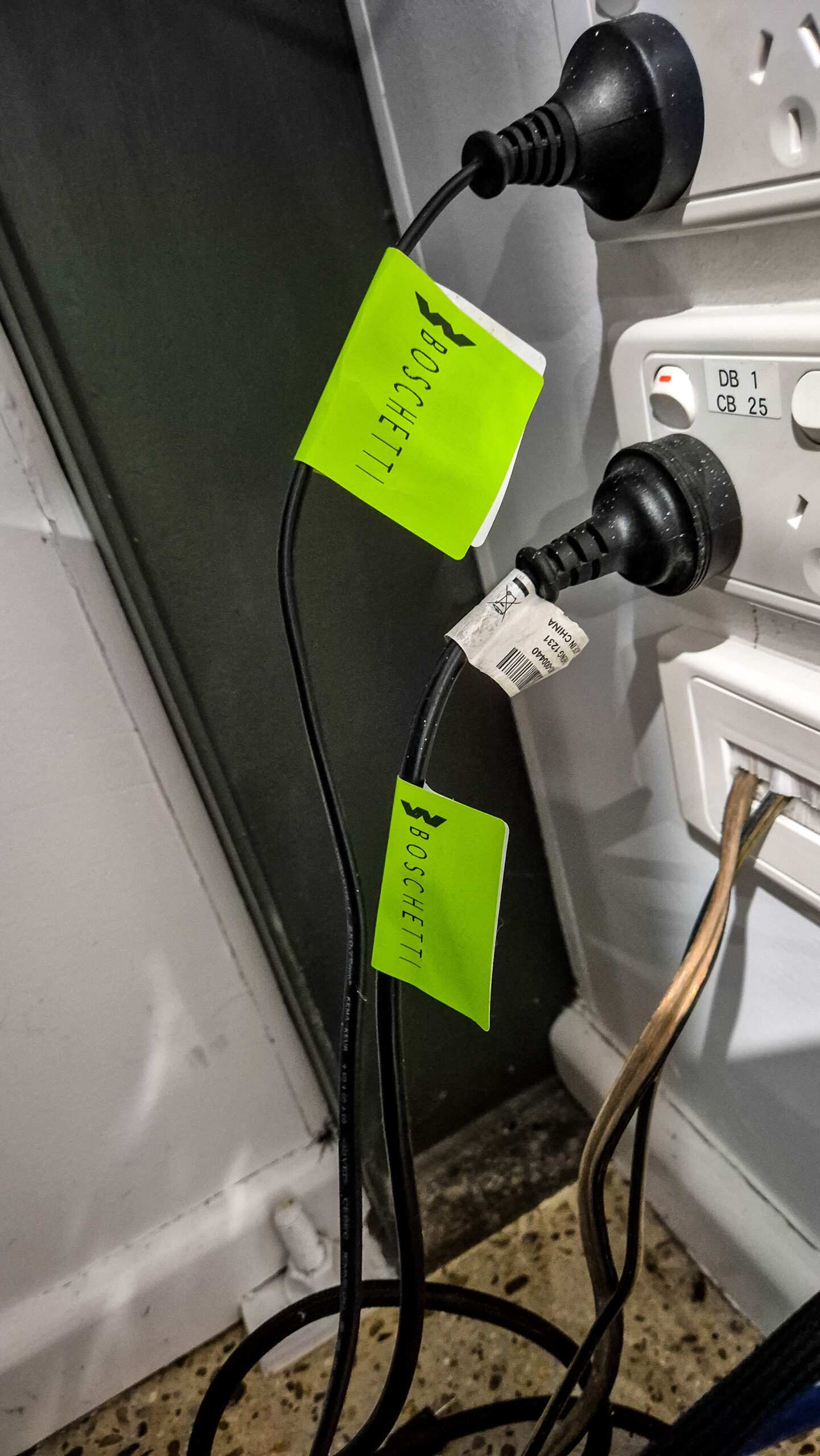

Testing & Tagging

All electrical equipment experiences wear and tear over time, which is natural. However, extensive wear can increase the risk of electrical incidents. Everyone – from homeowners to workplace employees – needs to have confidence that the equipment they use is safe. That is where testing and tagging comes in. Testing and tagging services in Albury are key to ensuring both the safety and compliance of electrical equipment in both workplaces and residential settings. Implementing a systematic test and tag regimen ensures that electrical equipment remains in optimal condition, minimising risks and enhancing safety protocols in Wodonga and Albury's diverse environments.

What is included in testing & tagging?

Test and tag procedures involve rigorous testing of electrical appliances and equipment to assess their operational integrity and safety. Our qualified electricians in Albury and Wodonga perform these tests in accordance with regulatory standards, affixing compliance tags to indicate that appliances have been inspected and deemed safe for use. This process helps prevent electrical hazards such as electric shocks and fires, promoting a secure environment for everyone. Our technicians not only conduct thorough inspections but also provide detailed reports documenting compliance with safety standards, which is essential for commercial properties in the region.

Our testing and tagging services

Here at Boschetti, we specialise in the following testing and tagging services:

Periodic Testing

Under AS/NZS 3760, equipment must be inspected regularly. The intervals for testing differ according to the equipment's location, operational environment, and risk levels. Generally, testing is required at intervals of 3, 6 or 12 months for many common items, and every five years for low-risk environments.

Visual and Electrical Testing

Our talented team of licensed electricians carefully inspect each appliance for any visual signs of damage to cables, connections, and covers. Once they have confirmed that the appliance is safe to inspect electrically, they proceed with testing insulation, earthing, and polarity to ensure electrical safety.

Tagging and Labelling

We apply relevant colour-coded tags to items that have been deemed safe, making it easy to see when a piece of equipment is due for inspection. Items that do not pass testing receive a danger tag and must either be repaired or replaced before they can be used within the workplace.

Record Keeping

To maintain full compliance with AS/NZS 3760, commercial businesses will require an asset register and a historical record of all tested items and results. We are here to provide accurate and timely testing and tagging reports to help you adhere to these requirements at all times.

Regular test and tag services are crucial in maintaining workplace safety, where electrical equipment undergoes frequent use and natural wear and tear. By working with our certified technicians for testing and tagging in Albury and Wodonga, businesses and homeowners can maximise safety while maintaining high levels of regulatory compliance. Contact the Boschetti team to learn more about how we can assist you in keeping your home and business electrical systems safe and compliant.